Color masterbatch is considered an industrial product that plays a significant role in the production of polymeric materials. This type of product consists of polymer particles combined with various agents such as pigments and specific additives. The primary goal of using color masterbatch is to achieve a suitable visual appearance and better performance in final products. Instead of directly adding pigments to the polymer, masterbatches act as efficient intermediaries, reducing issues related to uneven color dispersion. This product is widely used in industries such as plastics and foam.

Introduction to Color Masterbatch

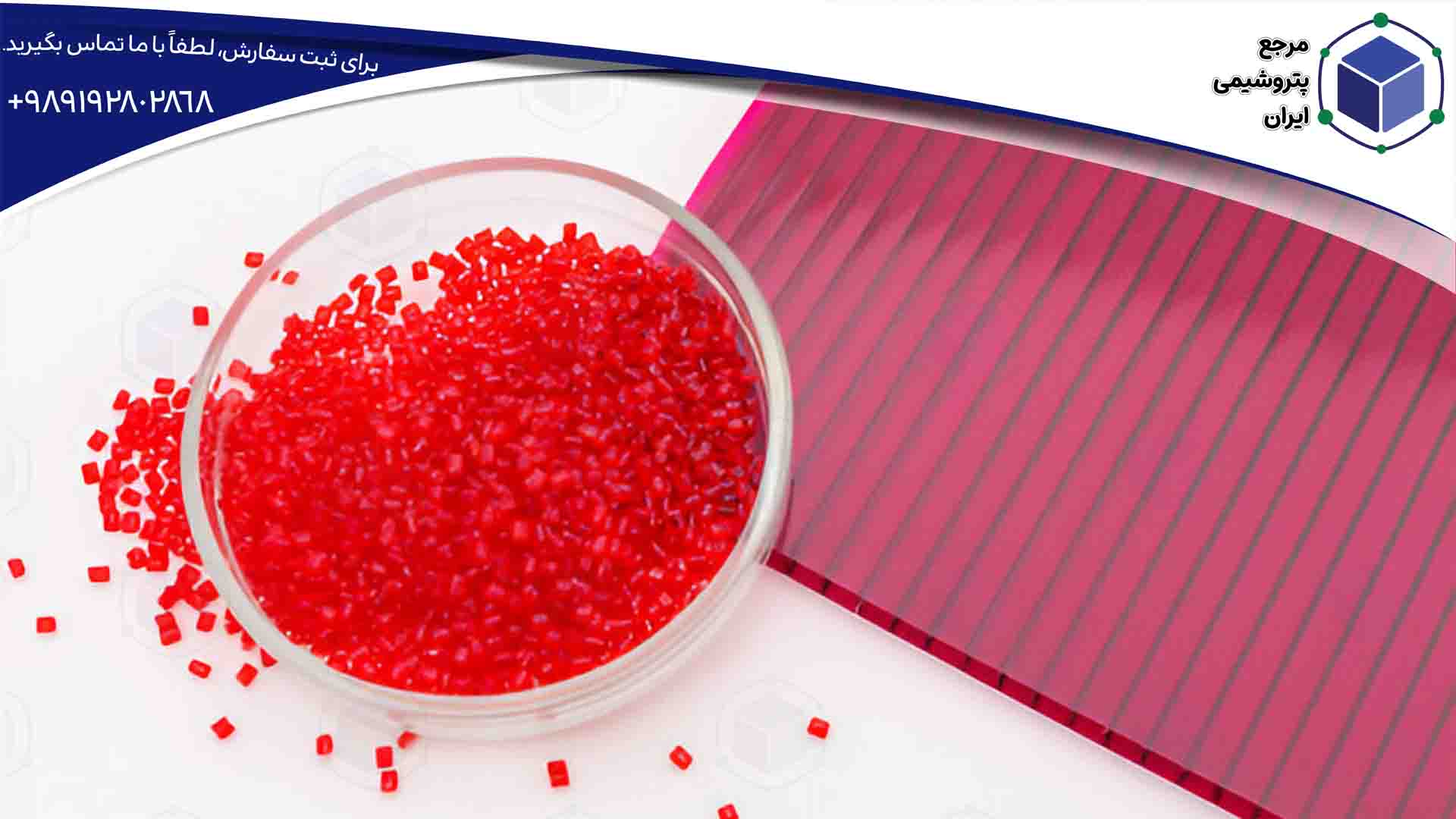

In the industrial world, color masterbatch is recognized as a powerful tool for altering the color and properties of polymeric materials. This product consists of a polymer base combined with various pigments and is produced in granular form. By using color masterbatch, manufacturers can add specific colors and characteristics to their products without needing complex processes. The main difference between them and conventional dyes is the higher pigment concentration and better compatibility with polymers. The use of masterbatches not only shortens production time but also reduces costs associated with trial and error in coloring.

Main Components of Color Masterbatch

Each color masterbatch includes several essential elements, each playing a specific role in its performance. The first element is the polymer base, which acts as a carrier for pigments and additives (such as polyethylene and polypropylene). Additionally, pigments, whether solid or liquid, play the main role in determining the final color of the product. Various additives such as waterproofing, flame retardant, or antistatic agents can also be added to the masterbatch to impart specific properties.

Classification of Masterbatch Types

Masterbatch types are classified based on various criteria. One of the main criteria is the type of polymer base, which may include PP, PE, PS, or other polymers. Additionally, based on the type of pigments and additives present in the masterbatch, these products can be divided into several categories. Some types of masterbatch include waterproof, flame retardant, and UV-resistant masterbatches.

Technical Specifications of Color Masterbatch

The technical specifications of color masterbatch include factors such as temperature rating, thermal shock resistance (withstanding process temperature), density, and the concentration of pigments present (typically between 20% to 80%). These specifications directly affect the masterbatch’s performance in the production process. For example, masterbatches designed for use in high-temperature environments must have adequate heat resistance. The particle size of the pigment also plays a key role in final quality; the smaller the particles, the more uniform the color. International standards such as ISO 9001 ensure the quality and safety of these materials.

Applications of Masterbatch Types

The applications of masterbatch are vast. These products are used in various industries such as household appliances, packaging, construction, and even automotive. Waterproof masterbatches are widely used in producing products intended for humid environments. Meanwhile, flame-retardant masterbatches are used in industries like cable manufacturing and electronic equipment.

In the production of plastic films, PVC pipes, toys, and even synthetic textiles, these products are utilized. The diversity in colors and customization options make them an ideal choice for specific projects.

Production Process of Color Masterbatch Types

The production of masterbatch involves stages of dry mixing, melting and extrusion, cooling, and granulation. First, pigments, polymer, and additives are blended in precise proportions. Then, they are melted in an extruder and formed into thin strands. Finally, these strands are cut and packaged as granules. Controlling temperature and process time determines the final quality.

Advantages of Color Masterbatch

Using color masterbatch allows manufacturers to manage the color and quality of their products with greater precision. These products reduce the need for separate pigment consumption due to the presence of concentrated pigments. Additionally, masterbatches can enhance the final products’ resistance to external factors like sunlight and water.

Using masterbatches offers significant advantages over powdered colors:

– Reduced energy consumption due to simpler mixing requirements.

– Uniform color across all parts of the product.

– Less waste from uneven pigment dispersion.

– Better environmental compatibility due to no airborne pigment particles.

Purchasing Color Masterbatch

Color masterbatch types have made the coloring process in polymer industries simpler and more cost-effective as an efficient solution. Given the technical diversity and wide applications, selecting the right product requires precise knowledge of raw material properties and production processes. New technologies in this field have paved the way for a bright future for modern masterbatch applications. Manufacturers must purchase from reliable suppliers to ensure the masterbatch quality is properly guaranteed.

Considering the critical role of masterbatch in polymer industries, accurate selection and proper use of these products can enhance the quality and appearance of final products. Moreover, with the variety of color masterbatch types, manufacturers can easily seek suitable options for their specific needs. Hence, Iran Petrochemical Reference can leverage its experts’ experience and customer requirements to provide high-quality, cost-effective color masterbatch to polymer manufacturers.