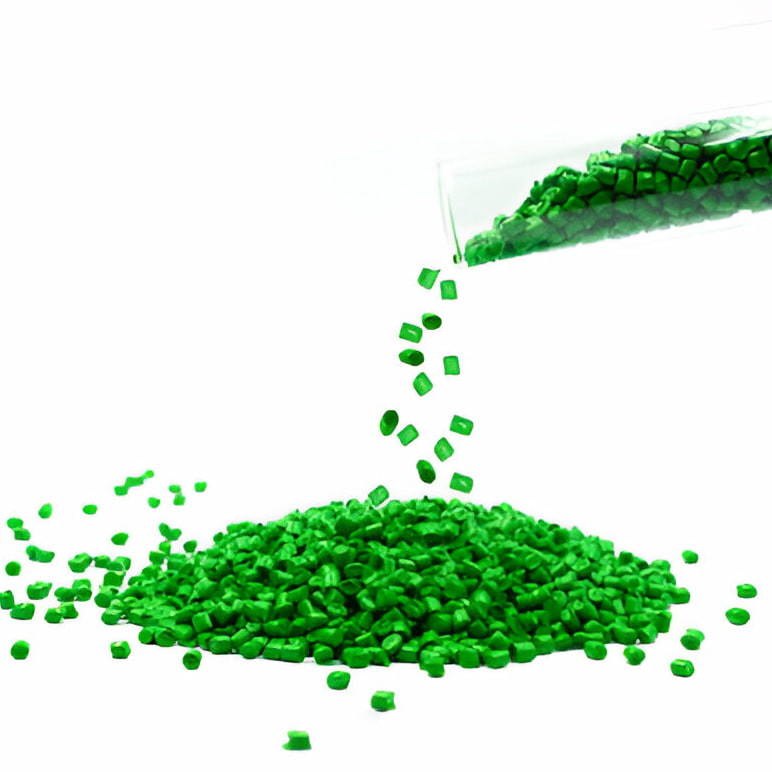

Polyethylene 0035 (HB0035) are two names for a widely used polymeric material known for its unique properties, utilized in various industries such as packaging, piping, and industrial parts manufacturing. This material not only offers high resistance but is also flexible and recyclable. In this article, we explore the characteristics, applications, advantages, and challenges of this polymer and examine why it has become so popular in industrial sectors.

Technical Features

Features

Melt Flow Index (MFI)

Density

Tensile strength at yield point

Elongation at yield point

Unit

g/10min

g/cm³

gr/cm2

%

Test Method

ASTM D 1238

ASTM D 1505

ASTM D 638

ASTM D 638

Value

0.35

0.959

290 min

900 min

Applications

- Resistant Packaging Films

- Construction and Industrial Pipes

- Chemical Containers

Introduction

If you look around, you will likely see many things made of Polyethylene 0035. From plastic bottles to industrial pipes, this material is virtually everywhere. HB0035 is another name for the same material, used more frequently in certain industries. Due to its high resistance, lightweight nature, and affordability, this polymer has become one of the most popular raw materials in today’s world.

Production of Polyethylene 0035

The production process of this polyethylene is somewhat similar to cooking, but instead of food ingredients, ethylene is used. This material is subjected to specific temperature and pressure conditions, forming long polymer chains. HB0035 is produced using methods that allow precise adjustments to enhance its final properties.

Properties of Polyethylene 0035

One reason for the popularity of Polyethylene 0035 is its high chemical resistance. It withstands acids, bases, and even some solvents. Additionally, HB0035 has exceptional mechanical strength, making it perform well under harsh conditions. These properties have led to its widespread use in industries ranging from packaging to construction and industrial fittings.

Applications of Polyethylene 0035

If you have ever used a plastic bottle, you have likely encountered one of the applications of Polyethylene 0035. This material is used to produce thin films and durable bags. HB0035 is also used in manufacturing high-pressure pipes and industrial fittings. Even small containers we use daily, such as water or shampoo bottles, may be made from this polymer.

Advantages of Polyethylene 0035

One of the biggest advantages of Polyethylene 0035 is its recyclability. It can be easily recycled and reintroduced into the production cycle. This not only reduces costs but also helps protect the environment. HB0035 is highly suitable for outdoor use due to its resistance to ultraviolet radiation.

Challenges of Use

Despite its advantages, this polyethylene has some challenges. One is its long decomposition period in nature, which can harm the environment. For this reason, scientists are working on developing biodegradable versions of this polymer to address this issue.

Future of Polyethylene 0035

With technological advancements, Polyethylene 0035 (HB0035) is expected to maintain its position in industries. Improving its properties and reducing its negative environmental impact are among the primary goals of future research.

Physical and Chemical Properties

Heavy-Duty Blow-Molded Polyethylene 0035 is a non-polar, highly crystalline thermoplastic with excellent chemical resistance and outstanding impact strength. Some technical specifications of this material include:

– Melt Flow Index (MFI): 0.35 g/10 min

– Density: 0.959 g/cm³

– Izod Impact Strength: Minimum 25 kg·cm/cm

– Tensile Strength at Break Point: Minimum 290 kg/cm²

– Melting Point: 130°C

The above physical and chemical properties are based on the product manufactured by Bandar Imam Petrochemical Company.

Applications of Polyethylene 0035

Due to its unique properties, this polymer is suitable for a wide range of applications. From producing detergent and motor oil bottles to manufacturing small containers with capacities ranging from 10 cc to 20 liters, all are applications of this material.

Processing Conditions for Polyethylene 0035

Polyethylene HB0035 can be processed in most blow molding machines. Using single-screw extruders with appropriate settings reduces thermal degradation and improves the quality of the final product.

Storage and Handling

This material should be stored in dry conditions at temperatures below 60°C. It must also be kept away from ultraviolet light to prevent degradation.

Safety and Environment

Polyethylene 0035 is not classified as a hazardous material, but dust generated from it can cause respiratory irritation. Therefore, using safety equipment and proper ventilation when handling this material is essential.

Recycling

Products made from this polymer are recyclable, and modern methods can be employed to reuse them. This contributes to waste reduction and environmental preservation.

Food Contact

This material’s compounds comply with European standards for food contact, making it suitable for producing food and beverage containers.

Packaging

The product is typically packaged in 25 kg bags for easy transportation.

Conclusion

Polyethylene 0035 (HB0035) are two names for an exceptional polymeric material with diverse industrial applications. Given its recyclability and high resistance, this material is expected to maintain its prominence in the future. Future research may offer more solutions to enhance its performance and reduce its negative impacts.

If you seek high-quality Polyethylene 0035 (HB0035) compliant with global standards, Iran Petrochemical Reference can be your trusted partner in this field. Leveraging technical expertise and extensive experience in polymer production and distribution, we offer the following services:

- Supply of Polyethylene 0035 and production of its compound with precise technical specifications tailored to various industries.

- Technical consultation for selecting suitable grades, optimizing production processes, and material consumption.

- Support for industrial projects in blow-molded containers, high-pressure pipes, and packaging products.

- Environmentally friendly solutions, including material recycling and reduction of production waste.

With Iran Petrochemical Reference, you not only ensure top-tier raw material quality but also transform technical and environmental challenges into growth opportunities through collaboration with our expert team. For more information and price inquiries, contact our specialists.