Polyethylene 0075 (Low-Density Polyethylene 0075) is a high molecular weight LDPE grade with superior mechanical properties, used for producing durable films, industrial bags, chemical bottles, and sensitive packaging. With its high flexibility, excellent impact resistance, and recyclability, this material holds a special place in industries. Its easy production process, competitive pricing, and compliance with health standards make it a smart choice for industrial projects.

Introduction to Low-Density Polyethylene 0075

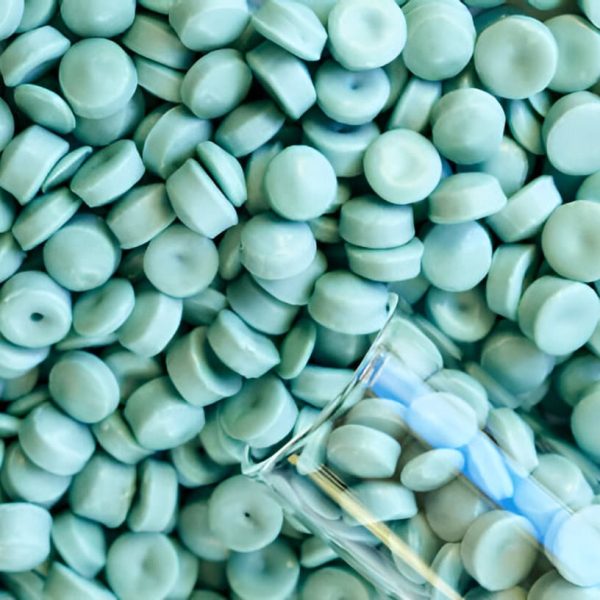

When it comes to polymeric materials, Polyethylene 0075 shines like a star in the industry! Also known as Low-Density Polyethylene 0075 (LDPE 0075), this material belongs to the family of low-density polyethylenes and is highly popular for producing thin films due to its exceptional flexibility and unmatched resistance. Imagine a material that is both soft and sturdy—like fabric used for comfortable clothing and durable bags that can handle heavy loads!

This product, with its combination of impact resistance and high elasticity, is ideal for manufacturing various packaging films. Even more fascinating, the antioxidants in it act like a permanent shield, preventing material degradation. Whether exposed to heat or sunlight, Polyethylene 0075 remains steadfast.

Features: A Blend of Strength and Softness

If we were to define Low-Density Polyethylene 0075, we’d say, “A material engineered to combine the best of both worlds!” Its Melt Flow Index (MFI) is 0.75, meaning it flows smoothly when melted and easily fills molds. Its low density (0.920 g/mL) ensures the final product is lightweight yet durable.

Another interesting aspect is its thermal tolerance. Its Vicat softening point is 95°C, meaning it retains its shape even in relatively warm environments. With a tensile strength exceeding 170 kg/cm² and the ability to stretch up to 300% without tearing, this polyethylene boasts remarkable features. In other words, if you make a bag from it, it won’t tear even when filled to three times its capacity!

The specifications mentioned in this article are based on the product of Bandar Imam Petrochemical Company.

Applications: From Shopping Bags to Chemical Bottles

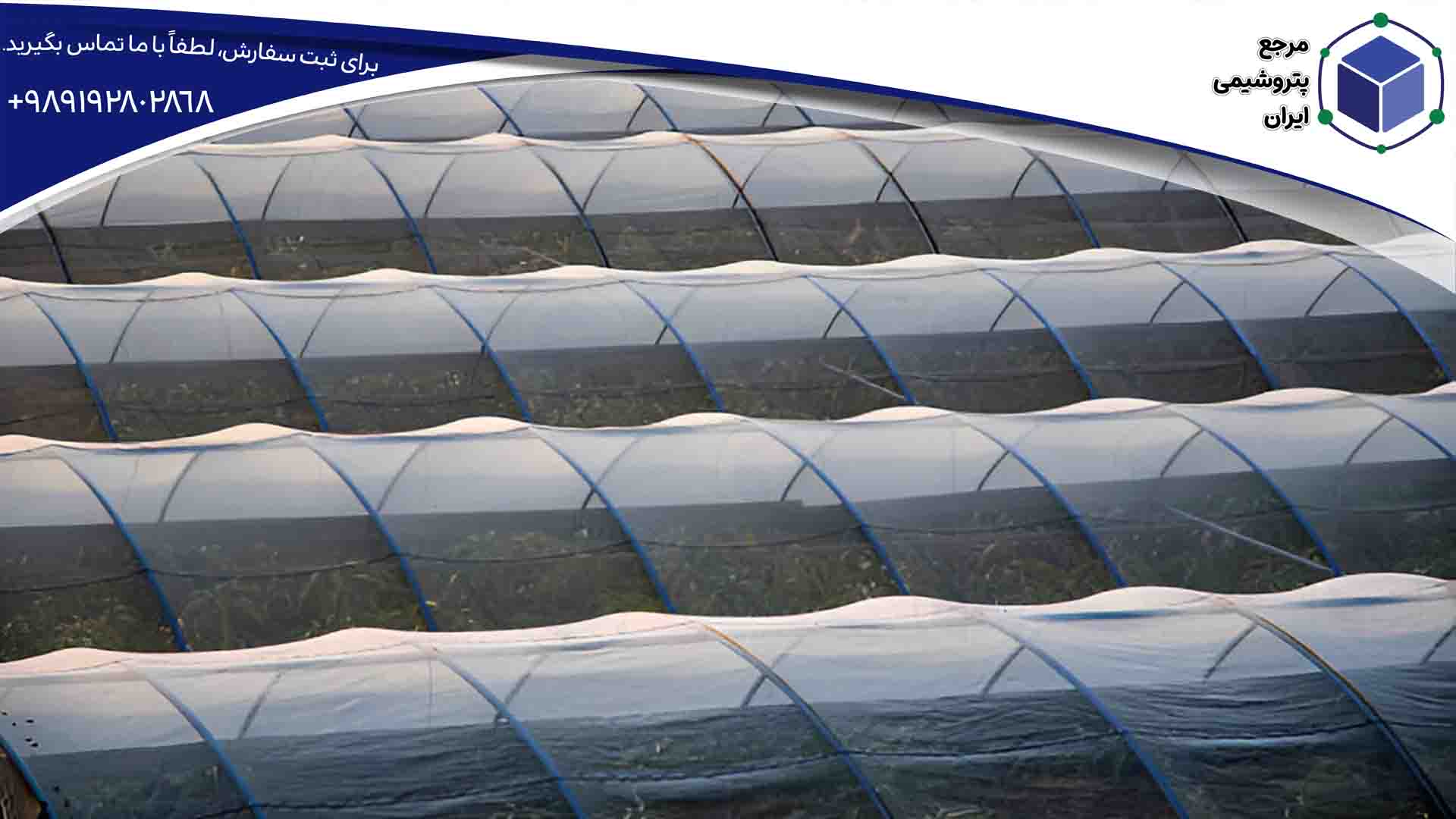

Polyethylene 0075 is so versatile that its footprint is visible across various industries. One day, you might see it as shrink wrap around a pharmaceutical package, and another day, as chemical storage bottles in laboratories! This material is used to manufacture heavy-duty transport bags, industrial protective covers, and even waterproof layers for roofing.

In the packaging industry, Low-Density Polyethylene 0075 excels. Films made from it are not only puncture-resistant but also shrink tightly after packaging, securing the product’s shape. For example, if you wrap a water bottle with this film, it’s like strapping it with a belt! It is even used in producing medical waste bags and greenhouse covers.

Production: Like Melting Chocolate!

The process of transforming Polyethylene 0075 into a final product resembles melting chocolate and molding it. A temperature range of 180–210°C is the sweet spot for extruding this material. However, there’s a golden rule: to preserve the film’s flexibility and strength, it must be rapidly cooled after exiting the mold. Imagine instantly placing molten chocolate in a freezer to stabilize its structure!

A blow-up ratio of 2:1 in blow molding machines is like setting the oven temperature when baking a cake. If this ratio isn’t maintained, the thin film might over-stretch in one direction, disrupting the balance of its properties.

Price: Why Is This Polyethylene More Expensive?

The price of Low-Density Polyethylene 0075, like any product, depends on various factors: crude oil prices, production costs, and even international policies. But why is this specific grade more expensive than standard polyethylene? The answer lies in its additives. The inclusion of antioxidants and stabilizers increases production costs but ensures the durability of the final product.

Another factor is its 25 kg packaging, which is cost-effective for bulk purchases. However, retail buyers may pay up to 20% more. Competition between domestic producers and imports also plays a key role in price fluctuations.

Environment and Health: Hassle-Free Recycling!

Good news for eco-conscious users: Polyethylene 0075 is fully recyclable! Modern methods allow it to be shredded, cleaned, and reintroduced into production cycles. Even factory waste, if clean, can be directly recycled into new products.

For health, this material is approved for food contact. During processing, minor fumes may be released, but proper ventilation eliminates risks. Avoid inhaling its dust—it’s like breathing household dust directly into your lungs!

Storage: Protect from Light and Moisture

To maintain the quality of LDPE 0075 for years, store it in a dry, cool place (ideally below 60°C). Sunlight is its enemy—like skin without sunscreen at the beach! High humidity may cause polymer pellets to clump. For long-term storage, UV-resistant bags are recommended.

Conclusion: A Material for All Seasons

Polyethylene 0075 is a “hidden hero” in the industry. From food packaging to industrial containers, this versatile material is always ready to tackle challenges. With its unique blend of softness, strength, easy processing, and environmental compatibility, it is a smart choice for sustainable industrial growth. Next time your shopping bag doesn’t tear or a chemical bottle doesn’t leak, remember—this special polyethylene might be the reason!

Looking for High-Quality, Customized Polymer Materials?

As the leading producer of polymer compounds, Iran Petrochemical Reference is ready to collaborate with industries to supply Polyethylene 0075 and other specialized grades. By combining technical expertise, modern equipment, and comprehensive support, we help you produce products with high strength, optimal flexibility, and competitive pricing.

From smart packaging to industrial components, our solutions turn your challenges into opportunities!

Contact us today for a free consultation!