Low-Density Polyethylene 020 (LDPE 020) is a low-density polymer with unique characteristics such as tensile strength, impact resistance, and easy processing, widely used in packaging, cable manufacturing, and molding industries. This article explores its features, production processes, standards, and environmental benefits.

Introduction to Low-Density Polyethylene 020

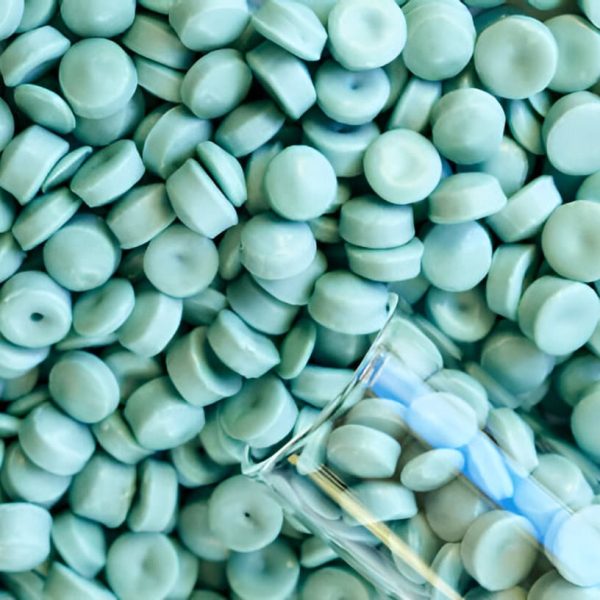

Low-Density Polyethylene 020 (LDPE 020) is a low-density polymer grade widely used in the packaging industry and plastic film production. Also known as Polyethylene 020, this material holds a special place in the market due to its superior mechanical properties and processing flexibility. Its molecular structure ensures that films made from it exhibit high tensile strength and remarkable impact resistance.

Key Features of Low-Density Polyethylene 020

LDPE 020 has a Melt Flow Index (MFI) of 2 grams per 10 minutes, enabling easy processing in extruders. Its density is 0.920 g/mL, and its softening point reaches 94°C. Unique properties like tear resistance, suitable transparency (up to 15% haze), and compatibility with various machinery make it an ideal choice.

Industrial Applications of Polyethylene 020

LDPE 020 is used in producing multi-purpose bags, mechanical component packaging, and low-stress cable insulation. Its low-temperature resistance also makes it suitable for dairy product packaging in multilayer films. In plastic injection molding, LDPE 020 is employed to manufacture high-durability components.

Processing and Storage Conditions

Processing of low-density polyethylene 020 requires mold temperature regulation between 160 to 180 degrees Celsius. The blow-up ratio must be at least 2 to maintain mechanical property balance. Cooling the film to ambient temperature during collection prevents layer adhesion and clumping.

Storing this product requires a dry environment, temperature below 60°C, and avoidance of ultraviolet light. Exposure to unsuitable conditions may cause chemical degradation, discoloration, and unpleasant odors.

Optimal Usage Conditions

For maximum efficiency, this polymer’s storage temperature must be below 60°C and away from UV light. Prolonged exposure to moisture or heat may cause premature degradation and discoloration. Suitable ventilation systems during production are essential.

Pricing and Influencing Factors

The price of polyethylene 020 is influenced by crude oil price fluctuations and production costs. Raw material quality and environmental standards also affect the final cost. Bulk purchasing is often more economical and reduces ancillary costs like transportation.

Storage and Recycling

Low-density polyethylene 020 can be recycled via shredding and washing. Production waste must be contamination-free to enter the recycling cycle. Recycled materials have lower quality and efficiency compared to new petrochemical materials.

Health and Environmental Considerations

This polymer is safe for food contact per EC 90/128/EEC guidelines. However, its dust may cause respiratory irritation. Safety equipment must be used to prevent dust exposure.

Conclusion

Polyethylene 020 plays a key role in various industries due to its unique mechanical and chemical properties. Adhering to production and storage conditions ensures material durability and efficiency. Advanced recycling methods enhance its environmental sustainability.

In which sectors do we operate?

Iran Petrochemical Reference, with years of experience in supply and technical consulting, is ready to provide you with the best solutions for using Polyethylene 020.

✅ Guaranteed Quality of Raw Materials

✅ Specialized Pre- and Post-Sales Support

✅ Competitive Pricing

Contact us and enjoy collaborating with a trusted brand in the petrochemical industry!