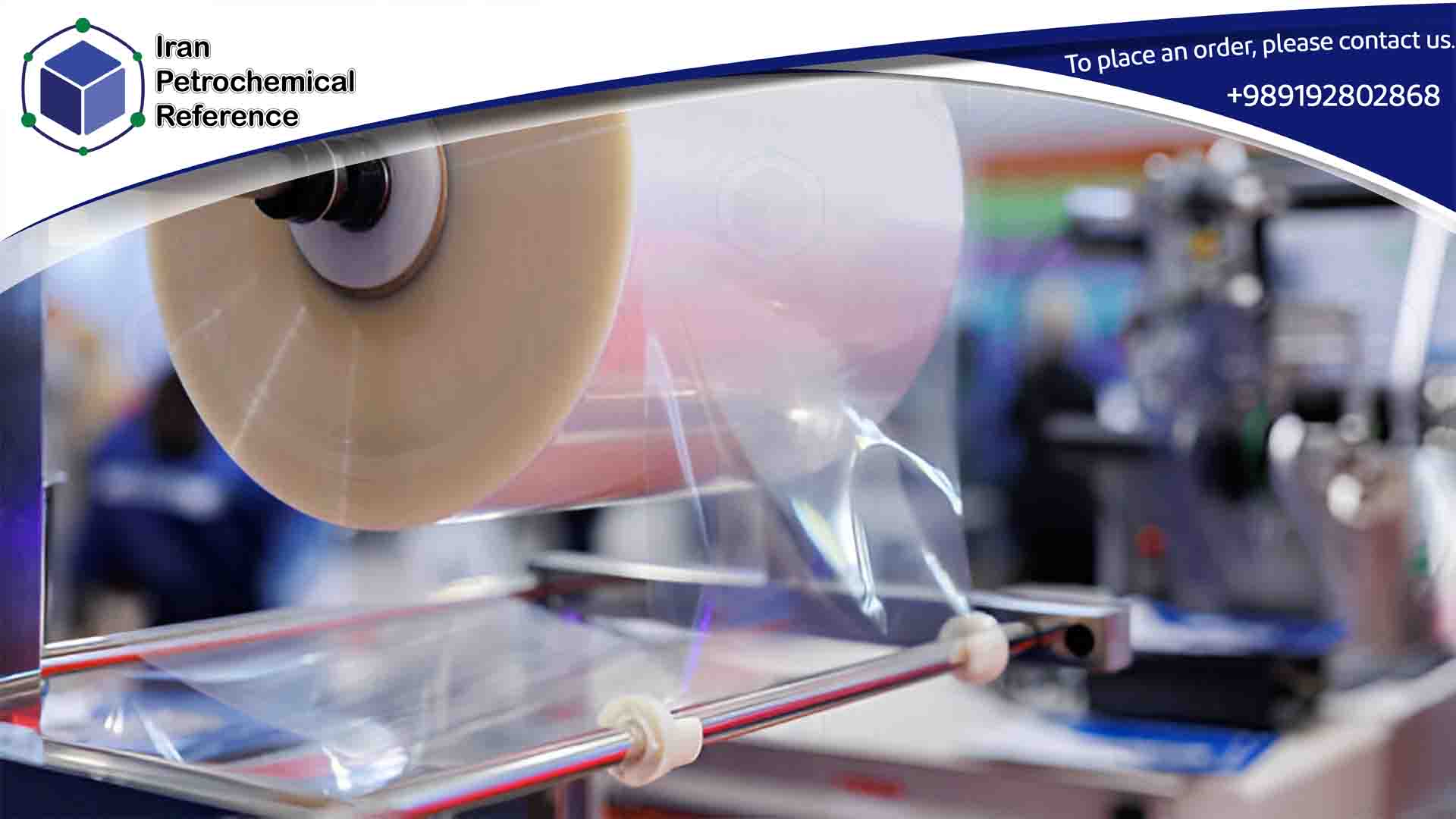

Polyethylene 5110 is mainly used for producing polyethylene films, nylon, and plastic parts. The common processing method is the blown film extrusion process. By combining this material with antioxidants and certain heavy polymers, a compound is produced that features properties such as heat resistance, environmental and chemical resistance, high flexibility, mechanical stability, and UV resistance. This blend significantly enhances packaging properties.

Technical Features

Features

Melt Flow Index (MFI)

Tensile strength (MD and TD)

Elongation at break (MD)

Elongation at break (TD)

Unit

g/10min

MPA

%

%

Test Method

ISO 1133

ISO 527-1,3

ISO 527-1,3

ISO 527-1,3

Value

10

55

580

620

Applications

- Blown film extrusion

- Single-layer or multi-layer packaging

- High-quality thin films

- Shopping bags and grocery bags

Polyethylene 5110 (HDPE) with high density

Grade HFI 5110 is a polymer with high molecular weight and a broad molecular weight distribution. This material is produced using the co-monomer 1-hexene and is specifically developed for producing thin films with excellent strength and stiffness. This polyethylene grade is suitable for producing a wide range of products, including high-strength shopping bags, retail bags, and high-quality thin films for single-layer and multi-layer packaging. The films produced with this material are easy to process and can be printed with high-quality graphics. Grade HFI 5110 is a product of Arya Sasol Petrochemical Company, manufactured under license from Basell, which can be a guarantee for the high quality of the product and its production processes.

Applications of Polyethylene 5110

Polyethylene 5110 is used in various industries due to its unique properties such as high strength, tear resistance, and excellent printability. Below is a more detailed explanation of the applications of this material.

-

Blown Film Extrusion

Polymer HFI 5110 is one of the best choices for the blown film extrusion process, in which thin films are produced by using air to form them into a tube.

Features:

– High mechanical resistance

– Precise thickness control

– Stability in the blowing process

Applications:

– Production of packaging films

– Protective coatings for industrial goods

-

Single/Multilayer Packaging

This grade is highly suitable for the production of single-layer or multi-layer packaging films. The films produced with this material are widely used in the packaging industry due to their high stiffness and resistance.

Features:

– Resistance to tearing and pressure

– High-quality graphic printing capability

Applications:

– High-quality graphic printing capability

– Industrial Packaging: such as chemicals or spare parts

-

Production of Shopping Bags

Polyethylene 5110 polymer is an ideal choice for producing shopping bags due to its excellent mechanical properties.

Features:

– High strength for carrying heavy goods – Recyclability to reduce environmental impact

Applications:

– Retail Shopping Bags – Branding bags with promotional printing capability

-

Production of High Strength Grocery Sacks

One of the primary applications of this material is producing grocery sacks, which must have high resistance due to the need to withstand weight and pressure.

Features:

– High tensile strength in both directions (MD and TD) – Tear resistance at corners and seams

Applications:

– Heavy-duty grocery sacks – Packaging of consumables like vegetables, fruits, and meat

-

High-Quality Thin Films

Polyethylene 5110 is specifically designed for producing high-quality thin films. These films are ideal for applications where both appearance and performance matter.

Features:

– Suitable transparency

– High-precision graphic printing capability

Applications:

– Luxury packaging for consumer goods

– Cover films for electronic products

-

Use in Printed Packaging

One of the important capabilities of this grade is its high printability. This feature has made Polyethylene 5110 widely used in printed packaging.

Features:

– Smooth and uniform surface for printing

– Maintaining print quality even at low thicknesses

Applications:

– Promotional packaging

– Branding bags for companies and stores

-

Industrial Multi-Layer Packaging for Industrial Applications

In heavy and chemical industries, durable packaging is essential for protecting goods. Polyethylene 5110 is an ideal choice for this type of packaging due to its high resistance to tearing and chemicals.

Features:

– Resistance to chemicals

– High pressure and weight tolerance

Applications:

– Packaging of chemical fertilizers

– Large bags (Big Bags) for transporting heavy materials

-

Stretch and Protective Packaging Films

This grade can be used in the production of stretch or protective packaging films, which are used to wrap and stabilize goods during transportation.

Features:

– Suitable flexibility – Tear resistance during stretching

Applications:

– Pallet packaging in transport industries – Protective coating for sensitive goods

Conclusion

Polymer HFI 5110 is an ideal choice for producing thin films and high-quality packaging applications. Its superior mechanical properties and high-quality printability make this grade a suitable choice for professional manufacturers.

Iran Petrochemical Reference has the ability to enhance the properties of Polyethylene 5110 by adding various additives to its formulation based on the specific needs and requirements of the customer. This approach results in the production of a custom-engineered compound that is fully compatible with the customer’s needs and intended applications.

For more information and specialized consultation, please contact the sales or technical support team.