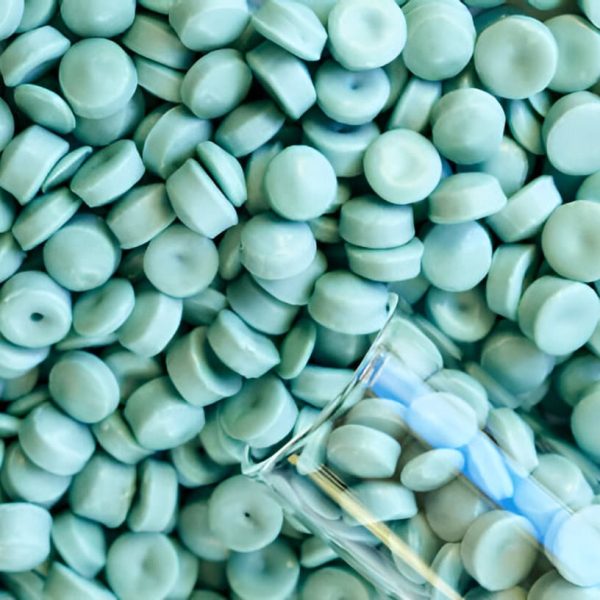

In the world of plastics, homopolymer polypropylene is recognized as one of the basic materials for manufacturing various products. This type of polymer plays an important role, especially in areas such as strand film extrusion, monofilaments, flat films, and various sheets due to its unique characteristics. In this article, we aim to examine the details of Polypropylene HP510L and its industrial applications.

Technical Features

Features

Melt Flow Index (MFI)

Bending modulus

Tensile strength at yield point

Elongation at yield point

Unit

g/10min

%

MPA

MPA

Test Method

ASTM D1238

ASTM D790

ASTM D638

ASTM D638

Value

6

1400

32

9

Applications

- Ropes and packaging threads

- Sheets for thermal shaping

- Thin sheets for stationery packaging

- Drinking straws

- Toothbrushes, brooms, and brushes

- Sieves

Introduction to Polypropylene HP510L

Polypropylene HP510L is a type of homopolymer polypropylene that, due to its special properties, is suitable for use in various extrusion processes. This polymer, with its excellent flowability, high processability, and reliable mechanical properties, is used in the production of products such as ropes, packaging threads, monofilaments for toothbrushes, brushes, and even thin sheets for stationery packaging.

Physical Properties of Polypropylene HP510L

One of the most important features of Polypropylene HP510L is its melt flow rate, measured according to ASTM D1238. This parameter reaches 6 g/10 min at a specific temperature and pressure (230°C and 2.16 kg). Additionally, the density is measured according to ASTM D1505 and reaches 0.9 g/cm³. These properties improve its performance in extrusion processes.

Mechanical Properties

Polypropylene HP510L has strong mechanical properties with tensile strength at yield of 32 MPa (according to ASTM D638) and a flexural modulus of 1400 MPa. These properties make it suitable for producing products that are subjected to pressure and stress. Elongation at yield is 9%, indicating good flexibility. Furthermore, its Izod impact resistance reaches 40 J/m at 23°C (according to ASTM D256), demonstrating high strength against mechanical impacts.

Thermal Properties

Polypropylene HP510L has suitable thermal properties that make it appropriate for use in various temperature environments. Its Vicat softening temperature reaches 152°C (according to ASTM D1525) and HDT reaches 84°C (according to ASTM D648), indicating its ability to withstand high temperatures. Additionally, its accelerated thermal aging at 150°C for 360 hours (according to ASTM D3012) demonstrates its long life in thermal environments.

Applications of Polypropylene HP510L

Ropes and packaging threads

Thin sheets made from this polymer, due to their suitable mechanical and thermal properties, are used to produce stationery pouches and beverage pouches. These sheets gain attention from manufacturers due to their high resistance to various conditions.

Thin Sheets and Pouches

Thin sheets made from this polymer, due to their suitable mechanical and thermal properties, are used to produce stationery pouches and beverage pouches. These sheets gain attention from manufacturers due to their high resistance to various conditions.

Toothbrushes, Brooms, and Brushes

Monofilaments produced from Polypropylene HP510L are used in the production of toothbrushes, brooms, and brushes due to their high strength and appropriate flexibility. These products attract consumers due to their high quality and long lifespan.

Processability and Thermal Forming

Polypropylene HP510L, due to its excellent processability, is suitable for use in thermal forming processes. This feature allows manufacturers to produce products with complex and precise designs.

Conclusion

HP510L is a versatile polymer used in various industrial applications based on its physical, mechanical, and thermal properties. This polymer, with its excellent processability and reliable mechanical properties, enables manufacturers to produce high-quality products. Therefore, Polypropylene HP510L is considered a suitable option for producing ropes, threads, toothbrushes, brooms, and even beverage pouches.

Polypropylene HP510L has been designed by Polypropylene Jam Company according to the specific needs of the industry and customers. We can engineer the properties of this polymer by adding appropriate additives for your various applications and offer you a customized product. This approach leads to creating a comprehensive compound that perfectly matches your needs and operational conditions.

For more detailed information and professional consultation on using this polypropylene in your specific applications, please contact the sales team or technical support at Iran Petrochemical Reference. We are ready to leverage our expertise and industry experience to provide you with tailored solutions that ensure optimal outcomes for your project.